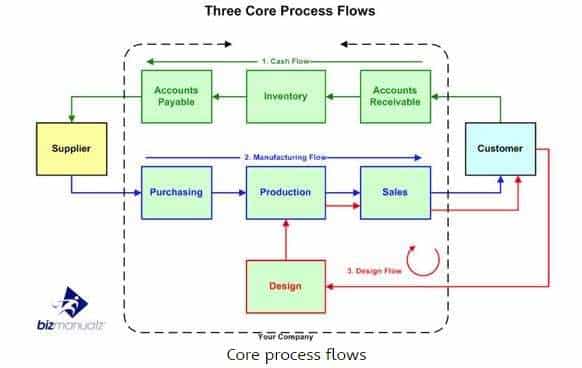

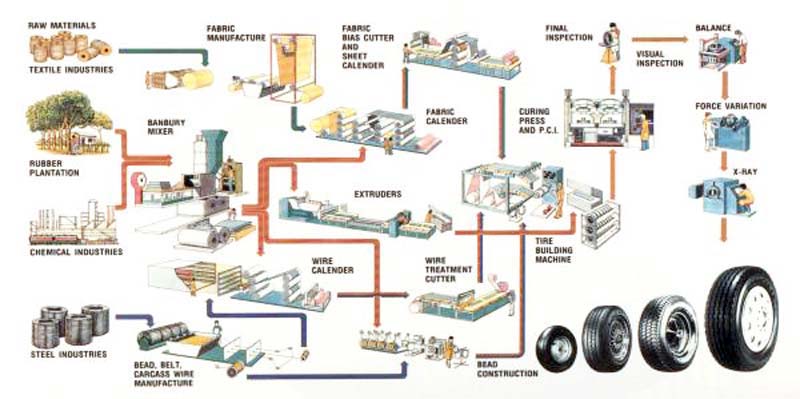

Glazing is the work of connecting the double layer glass with the curtain wall assembled with aluminum panels and extruded bars, and can be done either in a glass processing plant or in a curtain wall assembly plant. Double layer glass is required for glazing. Extrusion, painting and processing and assembly are required for the production of aluminum panels, extruded bars, and aluminum boards. The production process of the unit type system can be more specifically classified into mold, extrusion, painting, processing and assembly, glazing, and packaging and shipping. In recent years, to take advantage of cost reductions and the specialization of manufacturing and production systems, the distributed production system has been increasingly adopted. The production system can also be divided into a batch production system by which all work units (extrusion, painting, assembly and processing, glazing, etc.) are carried out in a single plant, and a distributed production system by which part or all of each of the work units is outsourced. The working process can be largely divided into construction-centered work including design of curtain wall members and system, delivery and lifting, and installation at the site, while manufacturing-centered work includes member production and assembly. 2) Analysis of the curtain wall production system As illustrated in Figure 3, the working process carried out by a curtain wall company is divided by work type. The validity of the proposed model is examined using the unit type glass and aluminum curtain wall made using the layer method, as it can be easily maintained, formed in diverse shapes, and facilitates high-rise building construction work. It is effective in terms of reducing the construction duration, but its weight per unit is heavy, and comprehensive and careful consideration should be given to the transport and lifting of the unit. The unit type curtain wall is most widely employed in high-rise buildings. The stick type curtain wall is assembled and then installed at the site, while the unit type curtain wall, produced as a completely assembled wall in a plant, is installed at a site without assembly. By installation method and shape, curtain walls can be classified into stick type curtain wall and unit type curtain wall. By material, curtain walls can be classified into curtain wall, glass and aluminum curtain wall, concrete curtain wall, and metal curtain wall. Curtain walls are generally classified by material, installation method, and type.

To examine the validity of the process design model for dry material production, the curtain wall was selected as the target material. In this study, the problems are dealt with by selecting appropriate manufacturers and production system at an early planning phase, in accordance with the object of the model presented in Chapter 3. Second, if an inappropriate plant has been selected in the process of selection, while the original intent may have been to improve productivity, an increased logistics cost may result due to the increase in travel distance caused by the distribution of production plants.

First, an increase in the travel time and distance between plants that carry out processes such as extrusion, painting, assembly, and glazing may cause the material delivery to be behind schedule. The following are the material logistics issues related with the curtain wall installation found in previous studies.

As the curtain wall is a long lead time item, which means that a relatively long time is required to procure materials to the site from the production plant, JIT (just-in-time) management is required.

MANUFACTURING PROCESS 3 INSTALL

In addition, to install a curtain wall, a large quantity of materials should be delivered to the site from outside, and repetitive work should be carried out. In terms of process management, it is placed in the critical path connected back and forth with framework and diverse types of finishing work. In terms of investment cost, curtain wall installation generally represents 10%-15% of the total construction cost, which is considerably high compared to other processes. Reasons for the selection Curtain walls are now being employed in Korean high-rise building construction projects more frequently than ever before.

0 kommentar(er)

0 kommentar(er)